Aceti Art 76 Abrasive Through-feed Machine

Aceti Art 76 abrasive through-feed machines for sheet, bar and box section up to 300mm wide.

The Aceti Art 76 abrasive through-feed machine allows finishing and satin-finishing work on parts with flat surfaces such as plates and sheets, bars and tubes with a square or rectangular section.

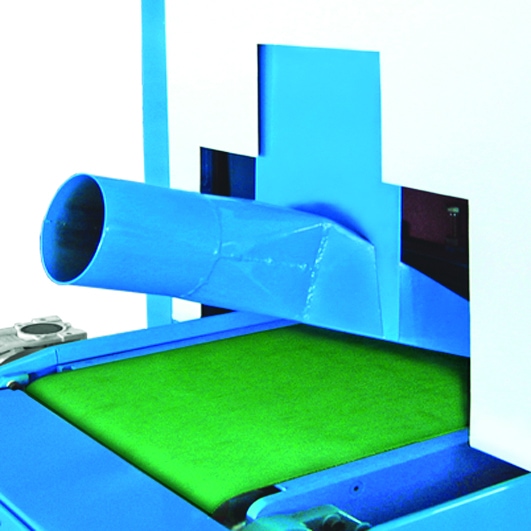

The processing takes place by means of an abrasive belt, which adjusted according to the thickness of the part, grinds a face for each single pass, combined with a conveyor belt that carries out the automatic advancement of the parts.

In addition to grinding, satin finishing and finishing in general, it is possible with the sole replacement of the abrasive belt, to carry out grinding and deburring work on parts sheared sheets or cut with thermal cutting such as oxy-fuel and laser.

Belts of any type of abrasive grain can be used with the machine to obtain different finishes.

The machine is built with components suitable for ‘wet’ processing, that is with the use of coolant which cools down the parts being processed, preventing them from deforming and guaranteeing a longer life for the abrasive belt as well as obtaining very high quality finishes.

The wet system is particularly suitable for the satin finishing of non-ferrous materials such as stainless steel, aluminium, copper, bronze, brass and also titanium, which have characteristics of high thermal conductivity especially when it comes to box section with thin wall thicknesses.

An abrasive wheel can be fitted to the outfeed of the machine performing either a higher grade of finish or even better deburring of the components.

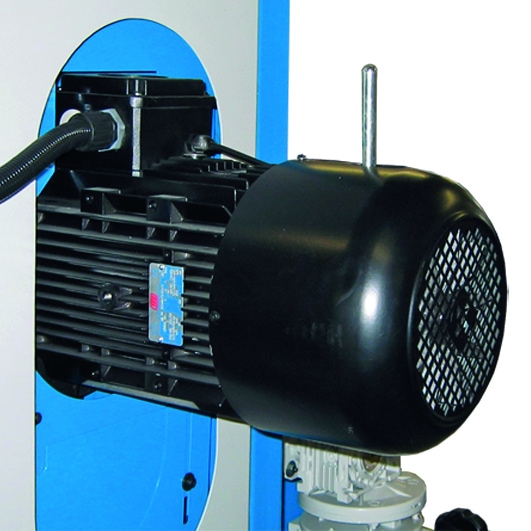

Can also be specified with twin speed or variable speed motors, outfeed air dryer, as well as infeed and outfeed rollers.

The machine is available in a variety of different configurations.

ART.76 – Single Belt Grinding Machine.

ART.76-1N+1S – Single Belt and 1 Brush Head.

ART.76-2 – Twin Belt Grinding Machine

ART.76-2N+1S – Twin Belt and 1 Brush Head.

ART.76-3 – Triple Belt Grinding Machine

ART.76-3N+1S – Triple Belt and 1 Brush Head.

Enquiry: Aceti Art 76 Abrasive Through-feed Machine

| Model | Art 76 | Art 76 – 1N+1S | Art 76-2N | Art 76-2N+1S | Art 76-3N | Art 76-3N+1S |

| Voltage | 415 v | 415 v | 415v | 415v | 415v | 415v |

| Power | 4.6 kw | 4.6 kw | 2 x 4.6kw | 2 x 4.6kw | 3 x 4.6kw | 3 x 4.6kw |

| Speed | Single | Single | Single | Single | Single | Single |

| RPM | 1500 rpm | 1500 rpm | 1500 rpm | 1500 rpm | 1500 rpm | 1500 rpm |

| Belt Size | 300 x 1900 mm | 300 x 1900 mm | 300 x 1900 mm | 300 x 1900 mm | 300 x 1900 mm | 300 x 1900 mm |

| Brush Size Ø x Width | 200 x 300mm | 200 x 300mm | 200 x 300mm | |||

| Max Width | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm |

| Thickness | 1 – 200 mm | 1 – 200 mm | 1 – 200 mm | 1 – 200 mm | 1 – 200 mm | 1 – 200 mm |

| Minimum Length | 140 mm | 140 mm | 140 mm | 140 mm | 140 mm | 140 mm |

| Weight kg | 625 | 655 | 1300 | 1340 | 1900 | 1940 |

| Dimensions (cm) | 125 x 120 x 210 | 125 x 120 x 210 | 160 x 120 x 210 | 160 x 120 x 210 | 220 x 120 x 210 | 220 x 120 x 210 |

Features

- Comes ready for wet grinding with supplied 70L tank capacity cooling system with triple filtration.

- Variable feed speed from 1 to 10m/min.

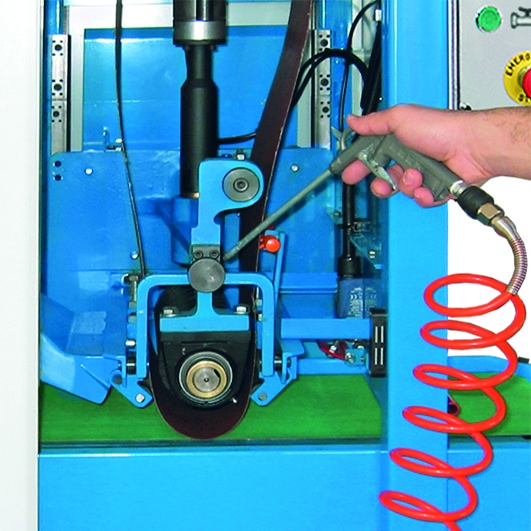

- Pneumatic Belt tensioning. (compressed air filter unit supplied)

- Low voltage electrical control panel.

- Motor with mechanical brake.

- Washing down gun for machine and part clean up.

- Micrometric meter thickness of the workpiece.

- Hand and over thickness protection strip with emergency stop.

- Airgun for cleaning of conveyor belt.

- Dust hood for dry working.

Need to know more about our Aceti Art 76 Abrasive Through-feed Machine?

Give us a call on +44 121 506 6095 or drop us an email to enquiries@echopkins.com

Alternatively you can request a callback below, fill out the form and we'll be in touch as soon as possible.